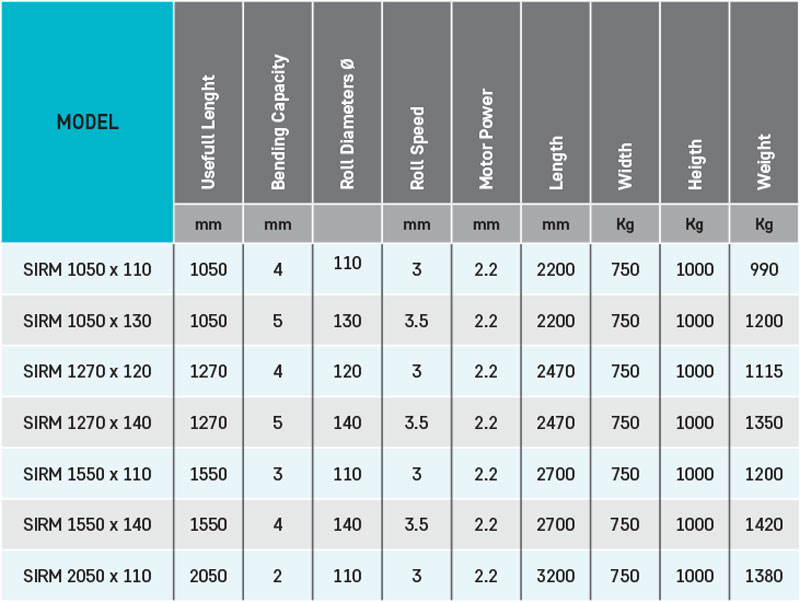

SIRM - ASSYMETRICAL 3 ROLLS PLATE BENDING MACHINES

• Two rolls powered by a single gearbox and gear system for top and bottom rolls.

• SAE 1050 quality certificated steel rolls with high tensile strength.

• Spheroid cast iron main frames.

• Mobile control panel by foot pedal. • Conical bending device.

• Manual Drop-End. • Top roll support system.

• Wire grooves at the end of the rolls (4/7/9/13)

OPTIONAL EQUIPMENTS

• Motorised back roll adjustment (Model SIRM 2550x140 produced standard with motorised back roll.)

• Precision bending with brake motor

• Digital readout for motorised rear roll

• Induction hardened rolls

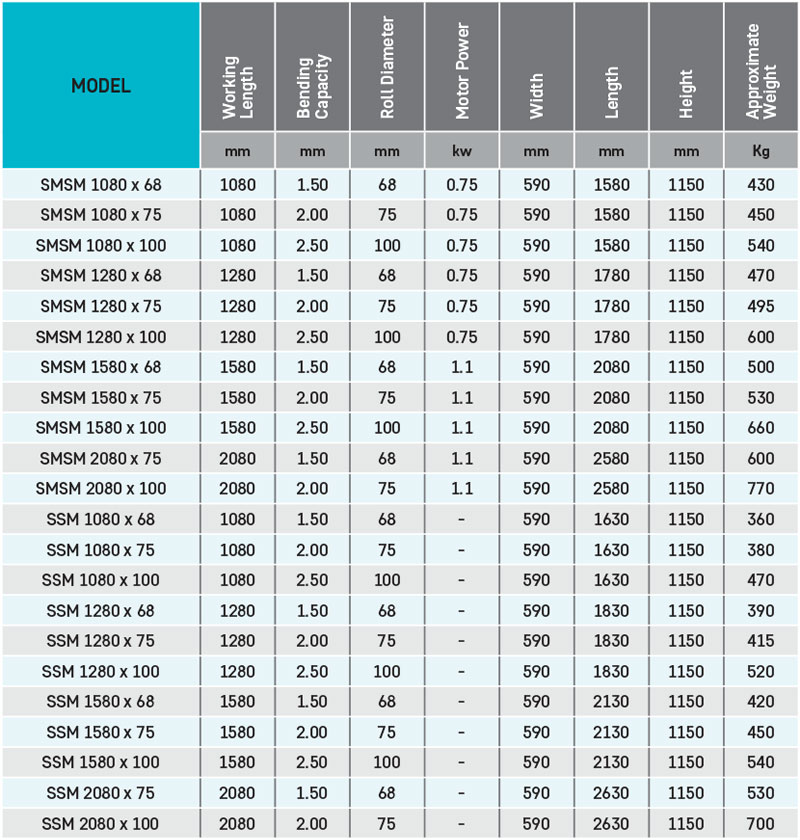

SMSM / SSM - 3 ROLLS MOTORISED & MANUEL PLATE BENDING MACHINES

• Cast iron main frames

• Main motor with reducer (SMSM types)

• Swing out openable top roll (drop end)

• Conical bending, pre-bending available

• Wire bending grooves

• Mobile control panel (SMSM types)

• SAE 1050 quality certificated steel rolls with high tensile strength

OPTIONAL EQUIPMENTS

• Induction hardened rolls

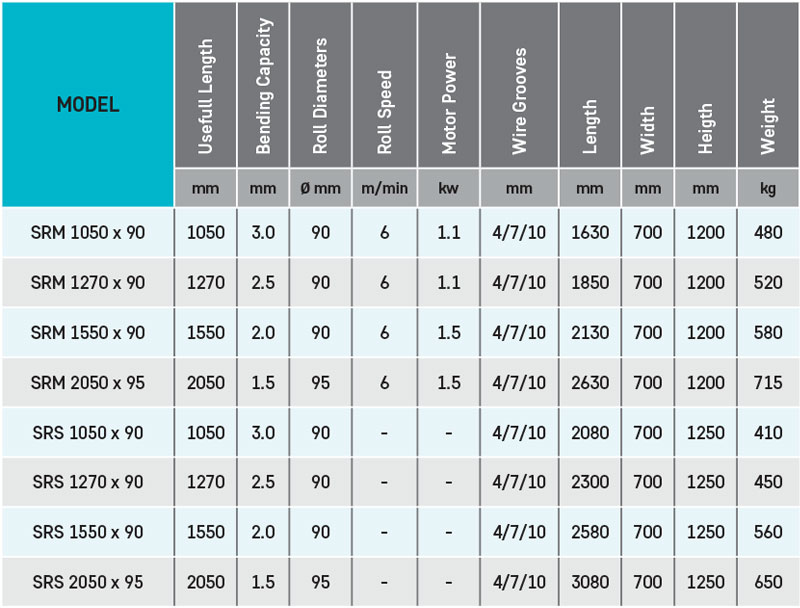

SRM / SRS 3 ROLLS MOTORISED and MANUEL PLATE BENDING MACHINES

• Top and bottom rolls powered by a single gearbox and gear system (SRM)

• SAE 1050 quality certificated steel rolls with high tensile strength

• Cast iron main frames

• Mobile control panel by foot pedal on rm models

• Conical bending device • Manual Drop-End

• Wire grooves at the end of the rolls

OPTIONAL EQUIPMENTS

• Motorised back roll adjustment

• Digital readout for motorised rear roll

• Induction hardened rolls

• Precision bending with brake motor on SRM models

• Full closed sheet covers

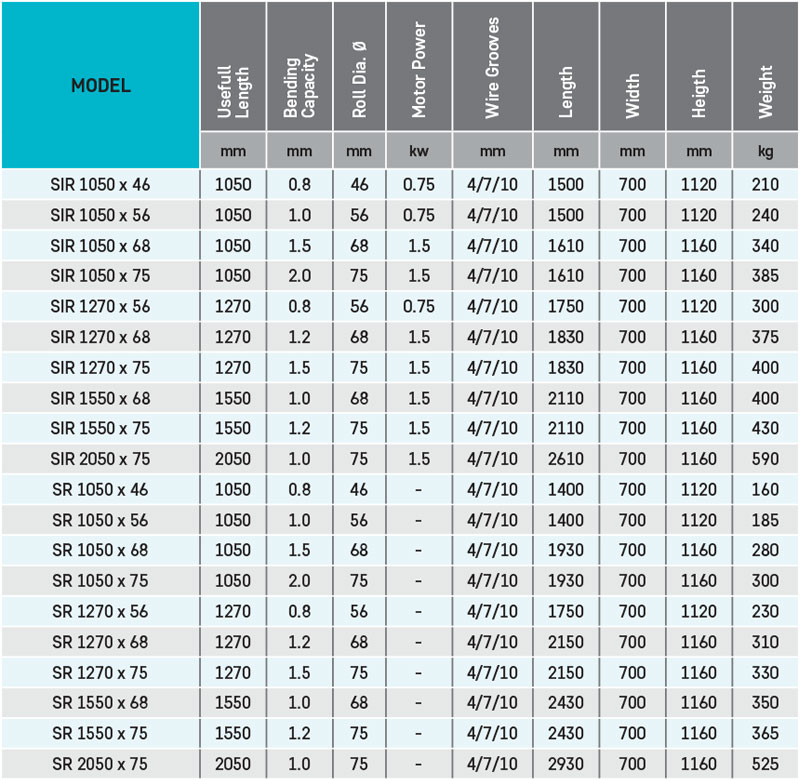

SIR / SR 3 ROLLS MOTORISED & MANUEL PLATE BENDING MACHINES

•Top and bottom rolls powered by a single Gearbox and gear system (SIR)

• SAE 1050 Quality Certificated steel rolls with high tensile strength

• Cast iron main frames

• Mobile control panel by foot pedal on (SIR models)

• Manual Drop-End

• Wire grooves at the end of the rolls

OPTIONAL EQUIPMENTS

• Induction hardened rolls

• Precision bending with brake motor on SIR models

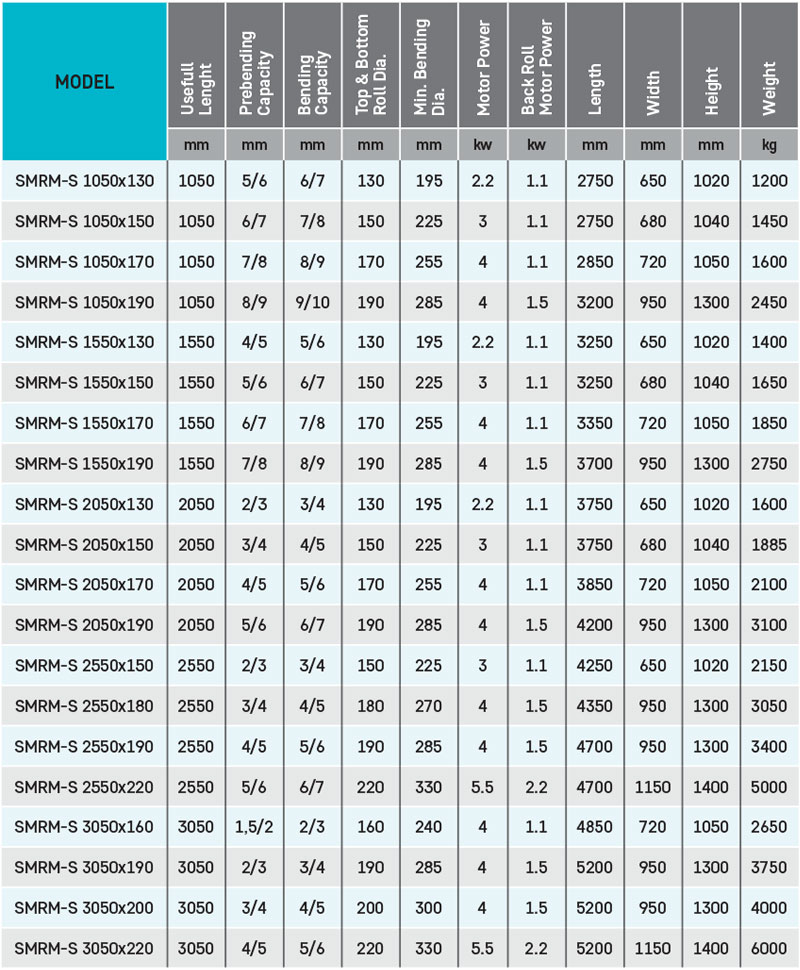

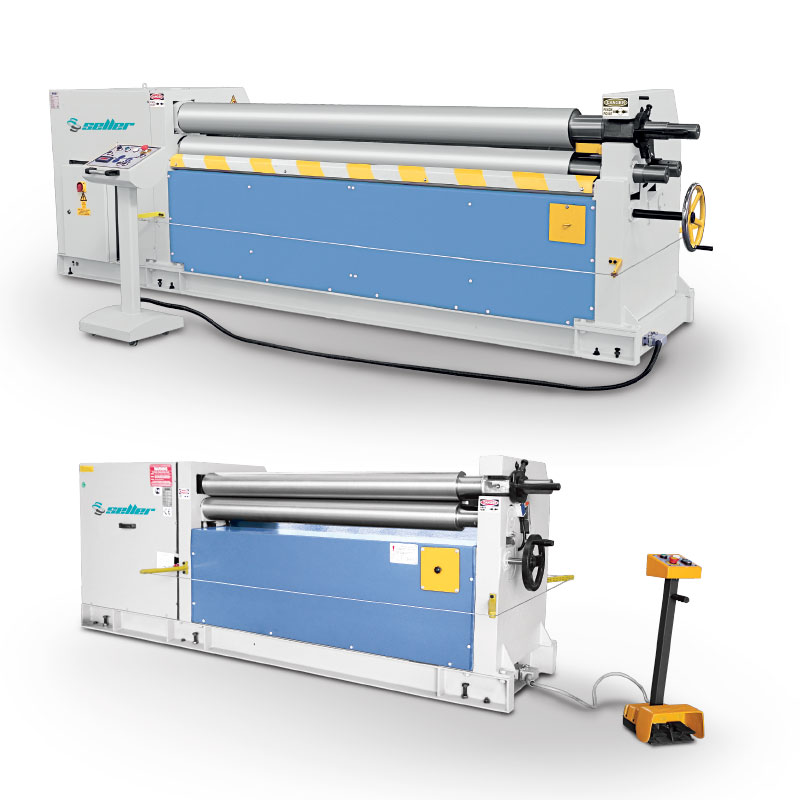

SMRM-S MECHANICAL ASSYMETRICAL 3 ROLLS INITIAL PINCH PLATE BENDING MACHINES

• This mechanical model is designed for light to medium jobs. It is used in jobs up to10 mm thickness materials. It is used in aluminium bendings, air conditioning channels, advertising panels and sheet metal covers.

• Welded steel main frames

• Two rolls powered by a single chain and belt driven helical type gearbox and gear system

• SAE 1050 (CK 45) quality certificated steel rolls with high tensile strength

• Mechanical manual openable Drop-End

Standard Eqiupments

- Mobile Control Panel

- Conical Bending Device

- Central lubrication system

- Top roll support system

- Precision Bending with Brake Motor

- Motorised Adjustment of Back Roll

Optional Eqiupments

- Digital read-out for rear (back) roll

- Induction hardened rolls

- Extended roll shafts for profile and pipe bending operation

- Profile and section bending rolls set

- Motorised bottom roll

- Plastic coated top roll for alucobond bending

- Variable stepless speed

- NC Control

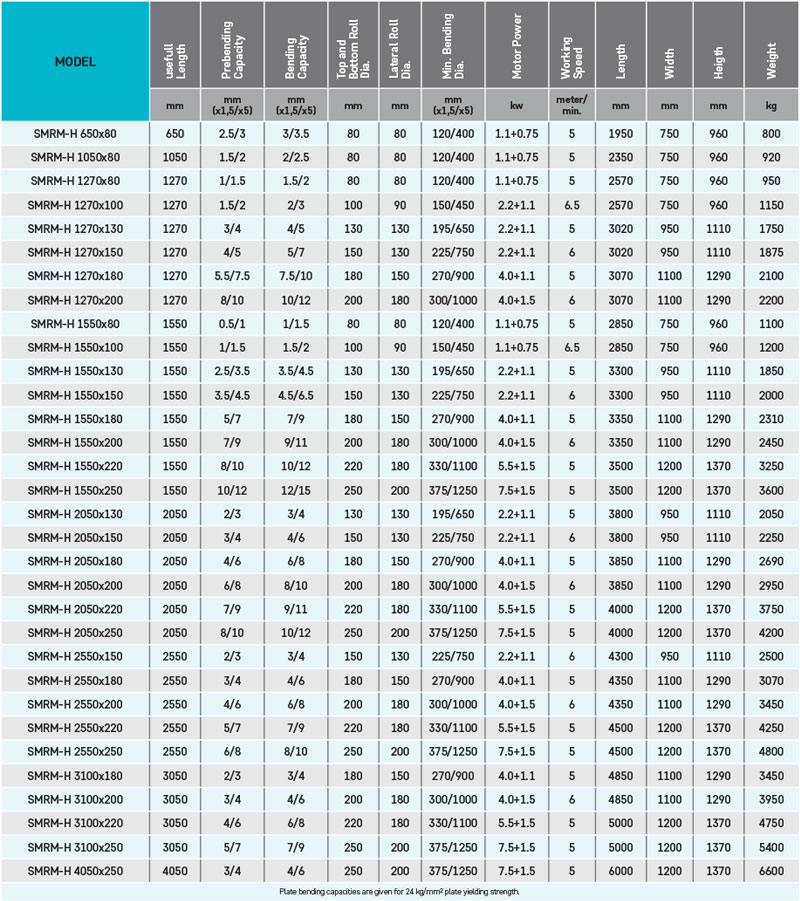

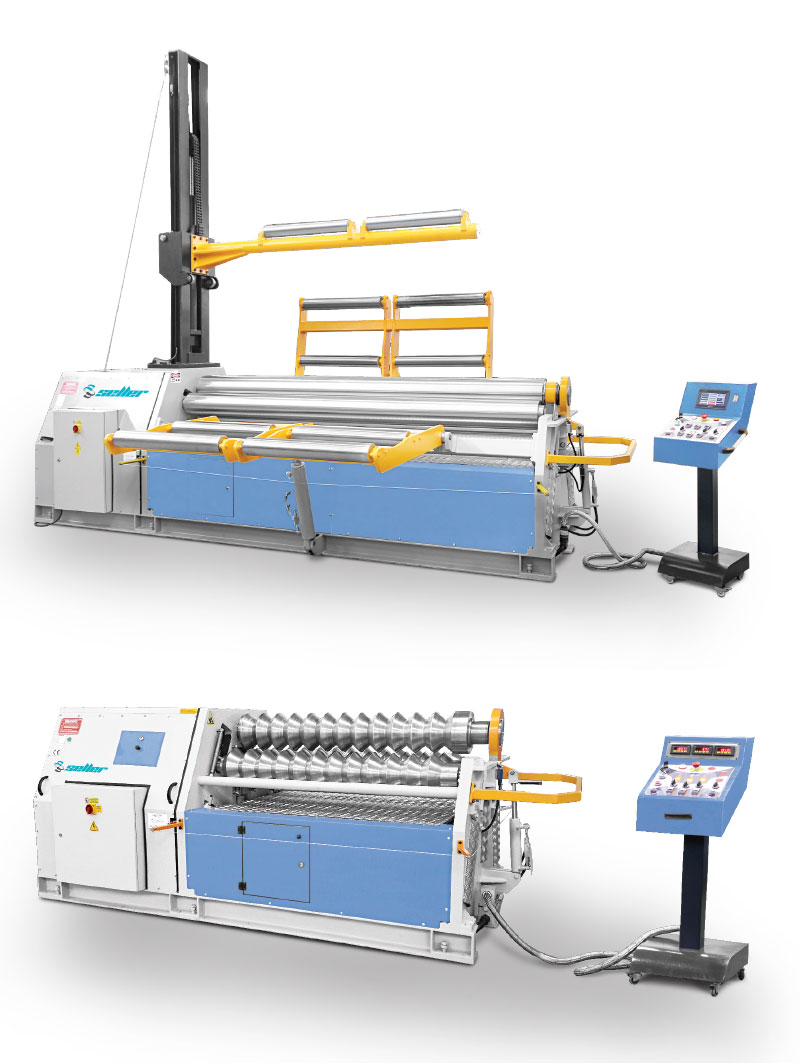

SMRM-H HYDRAULIC ASSYMETRICAL INITIAL PINCH 3 ROLLS PLATE BENDING MACHINES

• This hydraulic model is designed for light to medium jobs.It is used in jobs up to 10 mm Thickness materials. It is used in aluminium bendings, air conditioning channels, advertising panels and machinery sheet metal covers.

• Welded steel main frames

• Hydraulic Drop-End

• Motor powered centralised rolls

• Hydraulic movement of back roll and bottom roll

• Main motor with brake system

• Conical bending, prebending available

• Planetary gearbox two rolls driven

Standard Eqiupments

- Back roll with ball bearings for thin sheet works

- SAE 1050 (CK45) certificated forged steel rolls with high tensile strength

- Hardened rolls

- 2 Pcs. digital read-outs

- Mobile control panel

Optional Eqiupments

- Overhead crane for large diameters

- Hydraulic lateral side supports for large diameters

- Ground and polished rolls

- Wire grooves on roll ends

- NC control

- Double speed working

- Adjustable stepless speed

- Hydromotor option

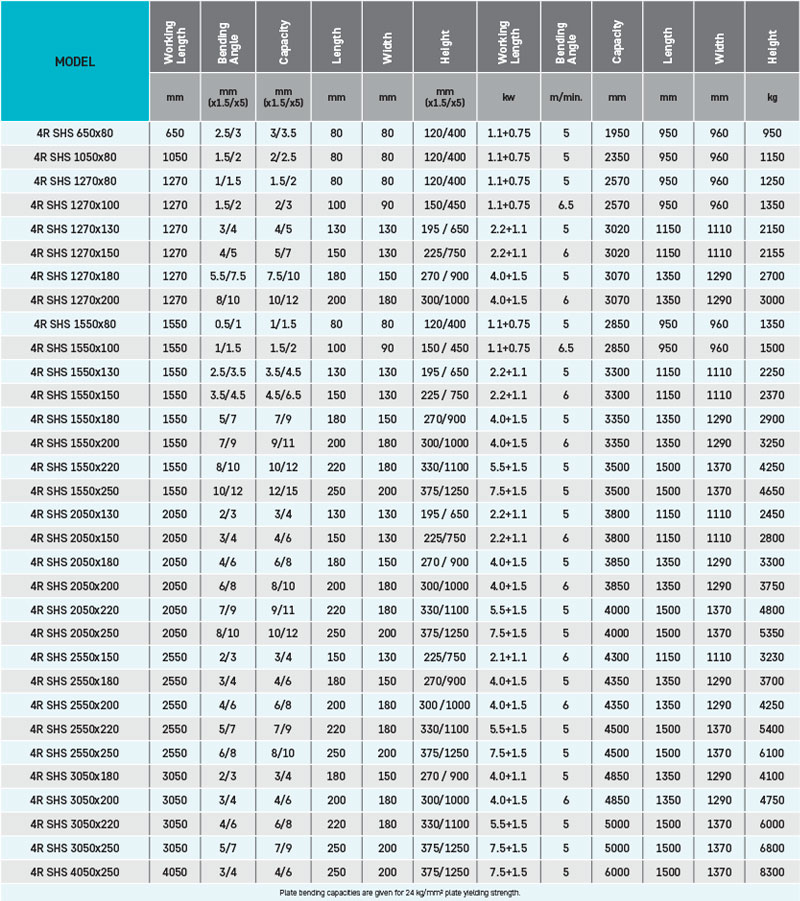

4R SHS HYDRAULIC 4 ROLLS PLATE BENDING MACHINES

• Very suitable for light and medium plates, aluminum or stainless steel

• Ferrules in full circle or varying radiuses can be done easily

• Pinch Roll and lateral rolls move with pyramid linear direct movement by hydraulic pistons

• Overload protection

• Top roll is powered by electrical motor and planetary gearbox. bottom roll powered with cardan joint system

• Three digital readouts for easy roll positioning

• Hydraulic Drop-End for easy removal of finished ferrule

• Easy operation with mobile control panel

• Welded steel frames

Standard Eqiupments

- Induction hardened forged or rolled SAE 1050 (CK 45) Steel Rolls

- Conical Bending device

- Hydraulic balancing system

Optional Eqiupments

- NC Control

- Overhead crane for large diameters

- Hydraulic lateral side supports for large diameters

- Ground and polished rolls

- Double speed system

- Infinitively variable speed

- Hydromotor for rotation

- Ejector system